Products

Description:

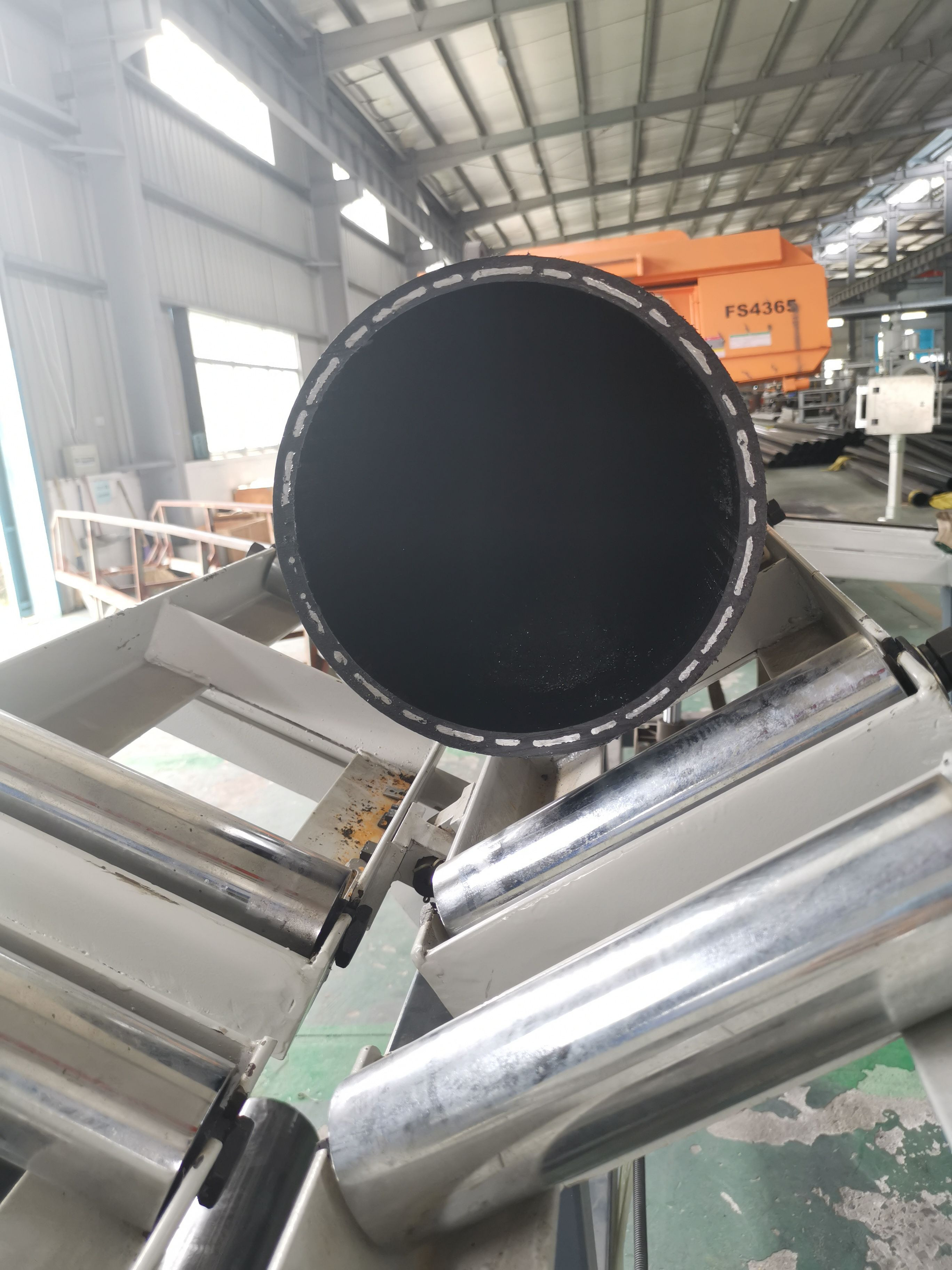

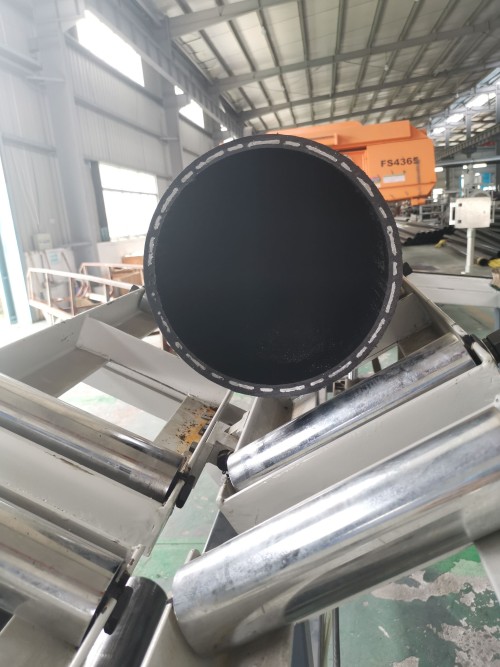

Fujian Shengyang Pipeline Technology Co., Ltd.s new steel-plastic composite pipes are constructed with a mesh pipe reinforced with cold-rolled perforated steel strips, and polyethylene ( PE ) or heat-resistant polyethylene ( PE-RT) as the primary composite material. The mesh steel pipe forms the middle layer of the composite pipes cross section, and then is molded with polyethylene. The polyethylene flows through the small holes in the mesh steel pipe to form inner and outer polyethylene layers, which tightly encase the mesh steel pipe within the inner layer.

The new-type steel-plastic composite pipes produced by Fujian Sinyo Pipe Technology Co., Ltd. are composited with polyethylene (PE) or heat-resistant polyethylene (PE-RT) as the main material and cold-rolled punched steel strip welded porous pipe as the reinforced skeleton. The porous steel strip is set in the middle layer of the cross section of the composite pipe and then composited with polyethylene. Inner and outer layers of polyethylene are molded through the holes of the porous steel strip and cover the strip tightly.

The small holes on the steel pipe become the most powerful and solid " rivets " , firmly maintaining the matrix of the inner and outer layers of the mesh steel belt - polyethylene, so that the inner and outer plastic layers can embrace each other through the mesh steel pipe, avoiding the peeling or separation of metal and plastic, solving the problem of insufficient strength and rigidity of pure plastic pipes, and also controlling the linear expansion coefficient of plastic.

Holes on the steel pipe are the most powerful solid "rivet", firmly molding together the inner and outer layers of polyethylene of the porous steel strip and enabling them to cover the pipe from both sides so as to avoid peeling or separation of metal and plastic, solve the problems of insufficient strength and stiffness of pure plastic pipe and control the linear expansion coefficient of plastic materials.

The compressive strength and heat resistance of the pipe are significantly improved. The unique structure can be used as tap water transmission, hot water transmission pipeline, secondary heating pipeline, power cable protection pipeline, air conditioning pipeline, industrial fluid transmission pipeline.

The pressure strength and heat resistance of the pipes have been significantly improved. The unique structure enables the pipes to be used as pipes for water transportation and hot water transportation, secondary heating pipes, power cable protective pipes, air conditioning pipes and industrial fluid transportation pipes.

Non-spraying, non-shedding; non-adhesive, non-separating; steel-plastic integration

Not by spraying, wont fall off; Not by adhesion, wont separate; Steel-plastic integration

Perfect structure that combines both rigidity and flexibility

Perfect structure with combination of inflexibility and yielding

Our company has also developed electric fusion pipe fittings with enhanced functions (the outer layer is a reinforcing layer of reinforced engineering plastics, and the inner layer is an elastomer blended with PE or PE-RT and rubber). The principle is to use the outer layer to reinforce the reinforcing layer of engineering plastics to improve the pressure resistance of the pipe fittings, and use the inner layer of PE-RT to weld with the pipeline. This significantly improves the overall mechanical condition of the hot water piping system during operation, significantly increasing the safety factor of the entire piping system. The pipes are connected using both electric fusion and flange connections, and the strength of the joints is no less than that of the pipe itself.

The company has also developed electrically welded pipe fittings which has stronger functions (the outer layer is covered with an extra layer of reinforced engineering plastic, the inner layer is an elastomer made from PE or PE-RT together with rubber). The principle of production is to use the reinforced layer to improve the pressure resistance level of the fittings, weld the pipes with the inner layer of PE-RT so as to greatly improve the overall mechanical conditions of hot water piping system while working and greatly increase the safety coefficient of the piping system. We adopt the two modes of electric welding and flange connection to connect the pipeline, so the strength of every joints is as high as that of the pipe itself.

Connection Modes:

◎ Electric Welding Connection ◎ Metal Buckle Connection

Combining the dual advantages of steel and plastic

Combining the advantages of both steel and plastic;

Good creep resistance and high lasting mechanical strength;

Excellent creep resistance and high mechanical strength;

Good thermal insulation performance, effectively reducing heat loss of the conveying medium;

Good thermal insulation performance, effectively reduce the heat loss of the medium;

It has good rigidity, impact resistance, dimensional stability, and moderate flexibility, combining rigidity and flexibility.

Remarkable rigidity and impact resistance, good dimensional stability and moderate flexibility, a combination of rigidity and flexibility.

No rapid cracking occurs.

Rapid cracking does not occur.

Double-sided anti-corrosion: The steel plate mesh is compounded in the plastic. The inner and outer surfaces of the pipe have the same anti-corrosion performance, are wear-resistant, have a smooth inner wall, have low conveying resistance, do not scale or wax, and have obvious energy-saving effects. It is very economical and convenient to use underground and in corrosive environments.

Double-sided anticorrosion: porous steel plate is composited in plastic so that both the inner and outer surface of the pipe have the same anticorrosion performance, wear resistance. The pipe has smooth inner wall with little transportation resistance, no scale, no wax, significant energy-saving effect and can be used economically and conveniently in underground and corrosive environmental conditions.

self -tracing properties: Due to the presence of the steel skeleton, buried steel skeleton plastic composite pipes can be located using conventional magnetic detection methods, thus avoiding damage caused by other excavation works. This damage is the most common damage to pure plastic pipes and other non-metallic pipes.

Excellent self -positioning : Because of the existence of steel skeleton, the buried plastic composite pipe with steel skeleton can be located by the usual magnetic detection method to avoid damage caused by other excavation projects. And this kind of damage occurs most for pure plastic pipe and other non-metallic pipe.

The product structure and performance can be adjusted conveniently and flexibly: the structure and performance of the product can be adjusted by changing the hole diameter, strength, mesh arrangement and distance of the steel plate , plastic layer thickness, and plastic type to meet different pressure resistance, temperature resistance, and corrosion resistance requirements.

The adjustments of structure and performance of products are easy and flexible. Different requirements of pressure resistance, temperature resistance and corrosion resistance can be met by changing the diameter, strength, mesh arrangement and distance of steel plate, thickness of the plastic layer and types of plastic.

Easy construction, installation and maintenance: The mesh steel belt polyethylene composite pipe is easy to carry and has low labor intensity. Generally, there is no need to use lifting equipment. The electric fusion connection is adopted, which is simple to construct and has low installation cost.

Construction, installation and maintenance are convenient: Carrying of Polyethylene (PE) composite pipes with porous steel strip requires low labor intensity and usually do not need lifting equipment. Electric welding connection mode makes construction easy and convenient. Installation cost is low.

The inner wall will not scale and the flow rate will not decrease with the increase of usage time.

The inner wall wont scale and the flow wont decrease as service time increases.

Good wear resistance, about 4 times that of steel pipe.

Outstanding wear resistance, about 4 times that of steel pipes.

Specific frictional resistance is low, with the equivalent roughness height of the inner wall being only 3/10 that of steel pipe (0.015/0.046) , and the flow resistance being only 1% of that of steel pipe, a level that can be maintained over time. Under the same delivery pressure, the transport capacity of perforated steel-belt polyethylene composite pipe can be increased by 30%-40% compared to steel pipe, and at the same flow rate, a smaller pipe diameter can be used.

Specific frictional resistance is low with the equivalent roughness of inner wall only about 3/10 that of steel pipe (0.015/0.046), flow resistance only 1% that of steel pipe and the figures can keep for a long time. Under the same conveying pressure, the conveying capacity of Polyethylene (PE) composite pipes with porous steel strip is 30%-40% higher than that of steel pipes, and shorter diameter can be adopted than that of steel pipes for the same flow rate.

Excellent sanitation performance, non-toxic, wont breed microbes, wont cause secondary pollution to water.

Long service life, can be used safely for 50 years, which is 5 to 7 times that of steel pipes, avoiding the waste of manpower, material resources and time caused by multiple construction and repairs.

Longer service life and is safe to use for 50 years, which is 5-7 times that of steel pipes, and can prevent wastes of manpower, material resources and time caused by repeated constructions and reparation.

Application areas of perforated steel belt polyethylene composite pipe

Chemical industry: process pipes and discharge pipes for conveying corrosive gases, liquids, and solid powders in the manufacturing of acids, alkalis, and salts, petroleum processes, fertilizers, pesticides, pharmaceuticals, chemicals, mining, rubber and plastics, and other industries.

Oil and gas fields: gathering and transportation pipelines for oily wastewater, gas field wastewater, oil and gas mixtures, and oil well reinjection polymer solutions, as well as secondary and tertiary oil recovery and gathering and transportation process pipelines.

Mines: slurry, tailings, ventilation pipes and engineering pipes.

Textile, printing and dyeing, and papermaking industries: process piping and discharge pipes for conveying corrosive media.

Municipal engineering: urban building water supply and drainage, drinking water, heat network return water, fire protection buried pipes, natural gas, and gas transmission pipelines.

Non-ferrous metals: used for conveying corrosive media in non-ferrous metal smelting.

Agriculture: deep well pipes, water filter pipes, culvert pipes, drainage pipes, ballast water pipes, ventilation pipes, etc.

Shipbuilding industry: sewage pipes, drainage pipes, ballast water pipes, ventilation pipes, etc. on board ships .

Seawater transportation: seawater desalination plants, coastal power plants, seawater transportation in port cities, submarine pipelines and optical cable (electrical cable) conduits, etc.

Thermal power engineering: process water return water transportation, waste residue transportation.

Expressways: buried drainage pipes and cable ducts.

A application F ield of Polyethylene ( PE) Composite Pipes with P orous S Teel S trip

Chemical industry: Manufacturing industries of acid, alkali and salt. Process pipes and discharge pipes for corrosive gas, liquid and solid powder transportation in industries of petroleum technology, chemical fertilizer, pesticide, pharmaceutical, chemical, mining, rubber plastics, etc.

Oil and gas field: Gathering and transportation pipelines, secondary and tertiary oil extraction and gathering and transportation pipelines of oil-bearing sewage, gas field sewage, oil-gas mixture and polymer solution refilled from oil wells.

Mine: Pulp, tailings, ventilation pipes and engineering pipes.

Textile, printing and dyeing and paper industries: Process pipe and discharge pipe for conveying corrosive medium.

Municipal engineering: Water supply and drainage, drinking water, heat-supply backwater, buried fire annihilator pipe, transporting pipe of natural gas and gas for urban buildings.

Nonferrous metal: Its used for transporting corrosive medium in nonferrous metal smelting.

Agriculture: Deep well pipe, filter pipe, culvert conveying pipe, drain pipe, ballast pipe and ventilation pipe, etc.

Shipbuilding: Sewage pipe, drainage pipe, ballast pipes and ventilation pipes, etc on ships.

Seawater transportation: Seawater transportation, submarine pipelines and optical cable (cable) conduits, etc. in seawater desalination plants, coastal power plants and seaport cities.

Thermoelectric engineering: Process water backwater transport, waste slag transport.

Highway: Buried drainage pipe, cable transmission pipe.