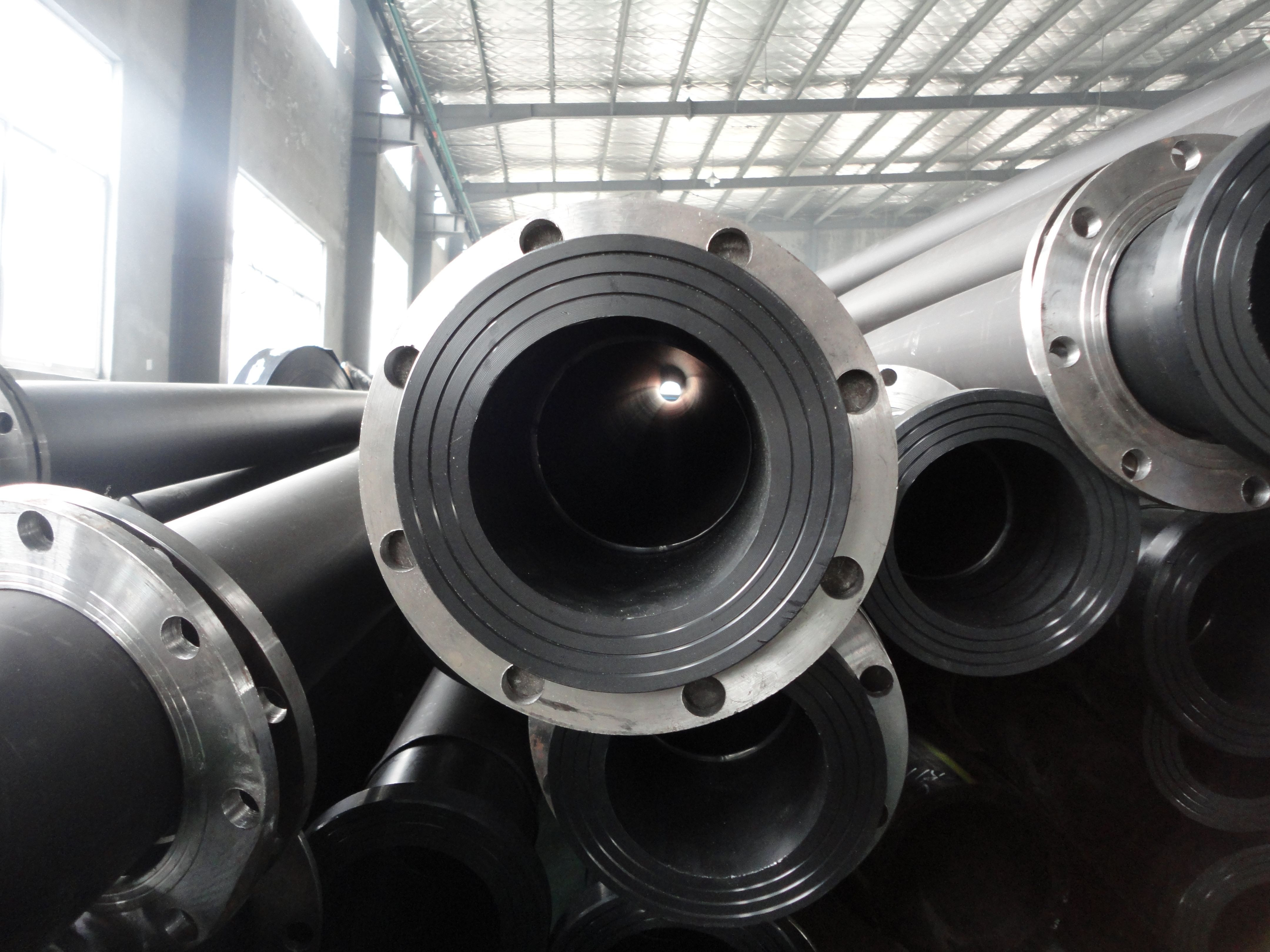

Products

Description:

Flame retardant / antistatic Inflaming Retarding /Antistatic

The antistatic and flame-retardant components of polyethylene pipe for underground coal mines are evenly distributed throughout the pipe body, ensuring that these properties remain stable over time. These properties meet national standards and are suitable for use in flammable and explosive environments underground.

The antistatic and flame-resistant ingredients are evenly distributed in the polyethylene pipes for underground coal mine, so the antistatic and flame re sistant property indexes wo nt be affected by long service time. Antistatic and flame re sistant properties are in line with the national standards, suitable for specific places of inflammable and explosive underground coal mine.

◎ Light Weight / Easy Installation

The density of polyethylene pipes used in coal mines is low, and the unit weight is only 1/8 of that of steel pipes and 1/3 of that of fiberglass pipes . Therefore, polyethylene pipes used in coal mines are easy to transport and install. Using them underground can greatly reduce the labor intensity of workers and improve work efficiency.

Polyethylene pipes for underground coal mines have low density with unit weight only 1/8 that of steel pipes and 1/3 that of glass steel pipes, so the transportation and installation are convenient, which can greatly reduce labor intensity of workers and improve work efficiency in the mines.

Aging Resistance and Rapid- cracking Resistance

Polyethylene pipes used in underground coal mines have good anti-aging properties, are not easy to become brittle, have good toughness, absorb impact energy, have an elongation at break of more than 350% , have good resistance to rapid cracking, and can effectively avoid fracture accidents.

Polyethylene pipe used in underground coal mine has excellent aging resistance and is not brittle. It has excellent toughness to absorb impact energy and its breaking elongation is more than 350%, so it has good rapid-cracking resistance to effectively avoid accidents of fracture.

◎Corrosion Resistance , No Scaling

Polyethylene pipes for underground coal mines are highly corrosion-resistant and non-scaling, making them particularly suitable for transporting highly alkaline water and water containing calcium and magnesium ions. They save on corrosion and descaling costs, have a service life far exceeding that of steel pipes, and offer 6-8 times the overall economic benefits of steel pipes.

Polyethylene pipe used in underground coal mine has strong corrosion resistance and wont scale, which makes it especially suitable for underground transportation of water with high alkaline and water containing ions such as calcium and magnesium. The pipe helps to save cost of anticorrosion and descaling, and its service life is much longer than that of steel pipe, the comprehensive economic benefit is 6-8 times that of steel pipe.

◎Self - lubricity

The inner wall of polyethylene pipe used in coal mine is smooth, and the equivalent absolute roughness is 2/5 of that of steel pipe, with low transmission resistance. Under certain conditions, the conveying capacity can be increased by 30% .

The inner wall of polyethylene pipe is smooth, the equivalent absolute roughness is 2/5 of steel pipe, and the conveying resistance is small. Under the same condition, the conveying capacity can be improved by 30%.